Where a laboratory requires a number of constant, but independent and variable pressure sources, the use of a pnuematic compressor is recommended. Depending on the capacity and volume of the unit, a series of pressure sources can be provded to various test stations around the laboratory.

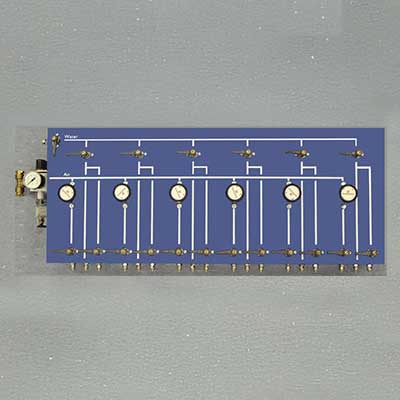

Compressed air must be controlled and delivered to a system designed to transfer the controlled pressure to the fluid (usually water), which applies the various test pressures, e.g., a confining pressure in a triaxial test. The pressure reducing panel share used in conjunction with a bladder-type air/water interface assembly. Each individual pressure take off from the reducing panel will require a bladder interface assembly. Connection of the reducing panels to the compressor/water trap outlet and to other reducing panels requires the use of nylon tubing.